Recent advances in design and performance optimization of pillow-plate heat exchangers: a critical review

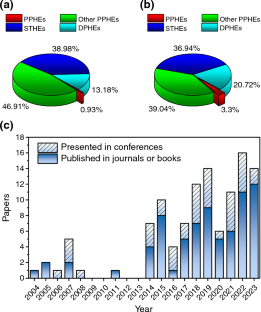

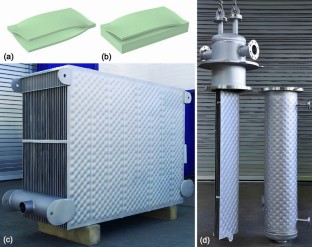

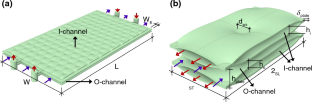

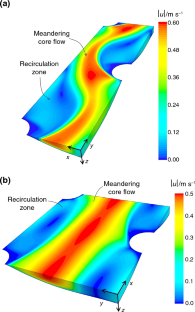

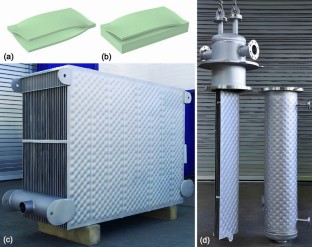

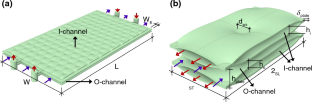

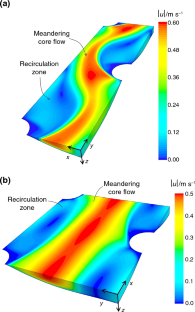

Over the last two decades, extensive research has been dedicated to the crisis stemming from fossil fuel usage and its environmental repercussions. This pressing concern has garnered substantial attention due to its potential to disrupt ecological equilibrium and sustainability. Pursuing more efficient and sustainable solutions in the heat exchangers realm has catalyzed the development and optimization of innovative designs, notably pillow-plate heat exchangers (PPHEs). These next-generation heat exchangers offer improved compactness and reduced material requirements, effectively tackling mounting concerns related to energy and resource consumption. Integrating such advancements can mitigate the adverse environmental impact, fostering a greener and more sustainable future. This paper presents an exhaustive review of recent progress in PPHE design and optimization, emphasizing their potential for widespread application across diverse industries. These innovative heat exchangers feature sleek, pillow-like channels, offering exceptional heat transfer capabilities and minimal pressure drops. These attributes position PPHEs as a compelling and eco-conscious alternative to traditional heat exchangers. Nevertheless, the intricate geometries of PPHEs pose challenges for comprehensive research, and existing studies underscore the limited number and scope of their industrial applications. This manuscript thoroughly examines the critical facets of the literature related to various aspects of PPHEs, encompassing manufacturing processes, thermohydraulic channel characteristics, design algorithms, and cost assessments. By meticulously identifying and emphasizing critical research gaps, this work not only underscores the need for further investigation but also sets the stage for future studies to enhance the reliability and performance of PPHEs as a heat transfer equipment solution.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save

Springer+ Basic

€32.70 /Month

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Buy Now

Price includes VAT (France)

Instant access to the full article PDF.

Rent this article via DeepDyve

Similar content being viewed by others

A Comprehensive Review of Thermal Performance Improvement of High-Temperature Heat Pipes

Article 12 January 2024

A comprehensive review of thermal enhancement techniques in microchannel heat exchangers and heat sinks

Article 28 September 2023

Pillow-Plate Heat Exchangers: Fundamental Characteristics

Chapter © 2018

Explore related subjects

Data availability

Data sharing is not applicable to this article as no new data were created or analyzed in this study.

References

- Mitrovic J, Peterson R. Vapor condensation heat transfer in a thermoplate heat exchanger. Chem Eng Technol. 2007;30(7):907–19. https://doi.org/10.1002/ceat.200700082. ArticleCASGoogle Scholar

- Tran JM, Piper M, Kenig EY, Scholl S. Pillow-plate heat exchangers: fundamental characteristics. In: Bart HJ, Scholl S, editors. Innovative heat exchangers. Cham: Springer; 2018. pp. 233–45. doi https://doi.org/10.1007/978-3-319-71641-1_7

- Piper M, Zibart A, Tran JM, Kenig EY., A numerical study on turbulent single-phase flow and heat transfer in pillow plates. In: 15th international heat transfer conference (IHTC15), Kyoto, Japan, 10–15 August; 2014. pp. 3591–602. https://doi.org/10.1615/IHTC15.hex.008929

- Dutka K. Laser welded pillow plate panels for austenitic steel tanks. Weld Int. 2012;26(9):692–6. https://doi.org/10.1080/09507116.2011.590697. ArticleGoogle Scholar

- Maletic B. Modelling and numerical simulation of fluid flow and heat transfer in thermoplates. Paderborn: University of Paderborn; 2009. Google Scholar

- Zibart A, Kenig EY. Numerical investigation of conjugate heat transfer in a pillow-plate heat exchanger. Int J Heat Mass Transf. 2021;165:120567. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120567. ArticleGoogle Scholar

- Guo Y, Qiu C, Xu M, Zhang W, Yan X, Li L. Crack failure analysis of laser 316L stainless steel edge joints in pillow plate heat exchanger used in oil refinery. Eng Fail Anal. 2021;122:105215. https://doi.org/10.1016/j.engfailanal.2021.105215. ArticleCASGoogle Scholar

- Eldeeb R, Aute V, Radermacher R. Investigation of thermal-hydraulic characteristics of pillow plate heat exchangers using CFD. In: 16th international refrigeration and air conditioning conference, Purdue, USA, 11–14 July; 2016. http://docs.lib.purdue.edu/iracc/1683

- https://www.scopus.com. Accessed 30 Aug 2023.

- https://scholar.google.com. Accessed 30 Aug 2023.

- Arsenyeva OP, Tran JM, Piper M, Kenig EY. An approach for pillow plate heat exchangers design for single-phase applications. Appl Therm Eng. 2019;147:579–91. https://doi.org/10.1016/j.applthermaleng.2018.08.083. ArticleGoogle Scholar

- Klemes JJ, Arsenyeva O, Kapustenko P, Tovazhnyanskyy L. Compact heat exchangers for energy transfer intensification: low grade heat and fouling mitigation. Boca Raton: CRC Press; 2015. pp. 72–93. https://doi.org/10.1201/b18862

- Maletic B, Mitrovic J, Influence of the thermoplate geometry on the heat transfer. In: 5th European thermal-sciences conference - Eurotherm 2008, Eindhoven, The Netherlands, 18–22 May; 2008.

- Tran JM, Sommerfeld S, Piper M, Kenig EY. Investigation of pillow-plate condensers for the application in distillation columns. Chem Eng Res Des. 2015;99:67–74. https://doi.org/10.1016/j.cherd.2015.03.031. ArticleCASGoogle Scholar

- Djakow E, Springer R, Homberg W, Piper M, Tran J, Zibart A, Kenig E. Incremental electrohydraulic forming - a new approach for the manufacture of structured multifunctional sheet metal blanks. AIP Con Proc. 2017;1896(1):080003. https://doi.org/10.1063/1.5008083. ArticleGoogle Scholar

- Zibart A, Spang B, Kenig EY. Determination of the burst pressure of pillow plates using finite element methods. Comput Aided Chem Eng. 2022;51:127–32. https://doi.org/10.1016/B978-0-323-95879-0.50022-9. ArticleCASGoogle Scholar

- Khalil I, Hayes R, Pratt Q, Spitler C, Codd D. Experimental and numerical modeling of heat transfer in directed thermoplates. Int J Heat Mass Transf. 2018;123:89–96. https://doi.org/10.1016/j.ijheatmasstransfer.2018.02.093. ArticleGoogle Scholar

- Khalil I, Pratt Q, Spitler C, Codd D. Modeling a thermoplate conical heat exchanger in a point focus solar thermal collector. Int J Heat Mass Transf. 2019;130:1–8. https://doi.org/10.1016/j.ijheatmasstransfer.2018.10.041. ArticleGoogle Scholar

- https://lob-gmbh.de/en/. Accessed 30 Aug 2023.

- Piper M, Olenberg A, Tran JM, Goedecke R, Scholl S, Kenig EY. Determination of characteristic geometrical parameters for the design of pillow-plate heat exchangers. Chem Ing Tech. 2014;86(6):1214–22. https://doi.org/10.1002/cite.201300159. ArticleCASGoogle Scholar

- Piper M, Olenberg A, Tran JM, Kenig EY. Determination of the geometric design parameters of pillow-plate heat exchangers. Appl Therm Eng. 2015;91:1168–75. https://doi.org/10.1016/j.applthermaleng.2015.08.097. ArticleGoogle Scholar

- Selvnes H, Hafner A, Kauko H. Design of a cold thermal energy storage unit for industrial applications using CO2 as refrigerant. In: proceedings of the 25th IIR international congress of refrigeration, Montréal, Canada, 24–30 August; 2019. pp. 1879–86. https://doi.org/10.18462/iir.icr.2019.0139

- Hesselgreaves JH. Compact heat exchangers: selection, design and operation. 2nd ed. London: Elsevier Science & Technology; 2016. Google Scholar

- Mitrovic J, Maletic B. Numerical simulation of fluid flow and heat transfer in thermoplates. In: 13th international heat transfer conference (IHTC13), Sydney, Australia, 13–18 August; 2006. https://doi.org/10.1615/IHTC13.p18.100

- Mitrovic J, Maletic B. Numerical simulation of fluid flow, heat transfer and pressure drop in thermoplates. In: 5th international conference on heat transfer, fluid mechanics and thermodynamics (HEFAT2007), Sun City, South Africa, 1–4 July; 2007.

- Mitrovic J, Peterson R. Study of single-phase convection and condensation in thermoplate heat exchanger (Part I). In: 5th international conference on heat transfer, fluid mechanics and thermodynamics (HEFAT2007), Sun City, South Africa, 1–4 July; 2007.

- Mitrovic J, Peterson R. Study of single-phase convection and condensation in thermoplate heat exchanger (Part II). In: 5th international conference on heat transfer, fluid mechanics and thermodynamics (HEFAT2007), Sun City, South Africa, 1–4 July; 2007.

- Mitrovic J, Maletic B. Numerical simulation of fluid flow and heat transfer in thermoplates. Chem Eng Technol. 2011;34(9):1439–48. https://doi.org/10.1002/ceat.201100271. ArticleCASGoogle Scholar

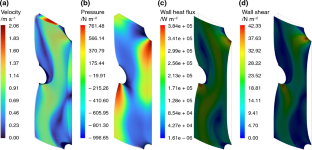

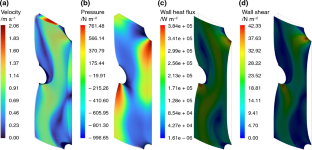

- Piper M, Zibart A, Tran JM, Kenig EY. Numerical investigation of turbulent forced convection heat transfer in pillow plates. Int J Heat Mass Transf. 2016;94:516–27. https://doi.org/10.1016/j.ijheatmasstransfer.2015.11.014. ArticleGoogle Scholar

- Eldeeb R, Ling J, Aute VC, Radermacher R. Heat transfer enhancement using approximation assisted optimization for pillow plate heat exchangers. In: 17th international refrigeration and air conditioning conference, Purdue, USA, 9–12 July; 2018. https://docs.lib.purdue.edu/iracc/2054

- Eldeeb R, Ling J, Aute, VC, Radermacher R. Weld shape optimization for pillow plate heat exchangers. In: 17th international refrigeration and air conditioning conference, Purdue, USA, 9–12 July; 2018. https://docs.lib.purdue.edu/iracc/2055

- Kumar S, Premachandran B, Subbarao PMV. Study on thermos-hydraulics in a pillow plate channel. Int J Therm Sci. 2019;145:106020. https://doi.org/10.1016/j.ijthermalsci.2019.106020. ArticleGoogle Scholar

- Goedecke R, Scholl S. Enlarged operation ranges for thermosiphon reboilers using thermoplates. In: Book of full papers - 10th international conference on distillation and absorption, Friedrichshafen, Germany, 14–17 September; 2014. pp. 63–8.

- Goedeck R, Scholl S. Experimental investigation of a pillow-plate heat exchanger as thermosyphon reboiler. Chem Ing Tech. 2015;87(3):244–52. https://doi.org/10.1002/cite.201400061. ArticleCASGoogle Scholar

- Goedecke R, Scholl S. Enlarged operation ranges for thermosiphon reboilers using pillow plates. Chem Eng Res Des. 2015;99:58–66. https://doi.org/10.1016/j.cherd.2015.05.037. ArticleCASGoogle Scholar

- Tran JM, Piper M, Kenig EY. Experimental investigation of convective heat transfer and pressure drop in pillow plates under single-phase through-flow conditions. Chem Ing Tech. 2015;87(3):226–34. https://doi.org/10.1002/cite.201400140. ArticleCASGoogle Scholar

- Piper M, Wecker C, Olenberg A, Tran J, Kenig EY. An experimental analysis of the topology and dynamics of a falling liquid film over the wavy surface of a vertical pillow plate. Chem Eng Sci. 2015;130:129–34. https://doi.org/10.1016/j.ces.2015.03.005. ArticleCASGoogle Scholar

- Siebeneck K, Popov W, Stefanak T, Scholl S. Pillow plate heat exchangers-investigation of flow characteristics and wetting behavior at single-flow conditions. Chem Ing Tech. 2015;87(3):235–43. https://doi.org/10.1002/cite.201400055. ArticleCASGoogle Scholar

- Rekstad IH, Eikevik TM, Jenssen S. Dimple plate heat exchangers for a seawater chiller using CO2 as refrigerant, design and testing. In: Proceedings of the 24th IIR international congress of refrigeration, Yokohama, Japan, 16–22 August; 2015. https://doi.org/10.18462/iir.icr.2015.0502

- Rekstad IH, Ladam Y. Evaluation of different evaporator and condenser concepts in sea water chillers using CO2 as refrigerant. In: Proceedings of the 12th IIR Gustav Lorentzen conference on natural refrigerants (GL2016), Edinburgh, United Kingdom, 21–24 August; 2016. https://doi.org/10.18462/iir.gl.2016.1119

- Tran JM, Linnemann M, Piper M, Kenig EY. On the coupled condensation-evaporation in pillow-plate condensers: investigation of cooling medium evaporation. Appl Therm Eng. 2017;124:1471–80. https://doi.org/10.1016/j.applthermaleng.2017.06.050. ArticleCASGoogle Scholar

- Kandlikar SG. A general correlation for saturated two-phase flow boiling heat transfer inside horizontal and vertical tubes. ASME J Heat Transf. 1990;112(1):219–28. https://doi.org/10.1115/1.2910348. ArticleCASGoogle Scholar

- Goedecke R. Naturumlaufverdampfung in Einem Kissenplattenapparat. Göttingen: Technische Universität Braunschweig; 2017. Google Scholar

- Zhang C, Wang D, Han Y, Zhu Y, Peng X. Experimental and numerical investigation on the exergy and entransy performance of a novel plate heat exchanger. Exp Heat Transf. 2017;30(2):162–77. https://doi.org/10.1080/08916152.2016.1179358. ArticleCASGoogle Scholar

- Arsenyeva OP, Piper M, Zibart A, Olenberg A, Kenig EY. Heat transfer and pressure loss in small-scale pillow-plate heat exchangers. Chem Eng Trans. 2018;70:799–804. https://doi.org/10.3303/CET1870134. ArticleGoogle Scholar

- Arsenyeva OP, Zibart A, Tran JM, Piper M, Kenig EY, Kapustenko PO. Friction factor correlation in small-scale pillow-plate heat exchangers for low-grade heat utilization. In: 12th conference on sustainable development of energy, water and environmental systems (SDEWES), Dubrovnik, Croatia, 4–8 October; 2017.

- Churchill SW. Friction factor equation spans all fluid flow regimes. Chem Eng J. 1977;84(24):91–2. Google Scholar

- Arsenyeva OP, Tran JM, Kenig EY. Thermal and hydraulic performance of pillow-plate heat exchangers. Comput Aided Chem Eng. 2018;43:181–6. https://doi.org/10.1016/B978-0-444-64235-6.50033-4. ArticleCASGoogle Scholar

- Arsenyeva OP. The hydraulic resistance in the small-scale pillow-plate heat exchangers. In: 2nd international scientific conference of chemical technology and engineering, Lviv, Ukraine, 24–28; 2019.

- Arsenyeva OP, Piper M, Zibart A, Olenberg A, Kenig EY. Investigation of heat transfer and hydraulic resistance in small-scale pillow-plate heat exchangers. Energy. 2019;181:1213–24. https://doi.org/10.1016/j.energy.2019.05.099. ArticleGoogle Scholar

- Goedecke R, Scholl S. Modelling and simulation of a pillow plate thermosiphon reboiler. Heat Mass Transf. 2019;55:95–104. https://doi.org/10.1007/s00231-018-02543-4. ArticleCASGoogle Scholar

- Lin W, Zhang W, Ling Z, Fang X, Zhang Z. Experimental study of the thermal performance of a novel plate type heat exchanger with phase change material. Appl Therm Eng. 2020;178:115630. https://doi.org/10.1016/j.applthermaleng.2020.115630. ArticleCASGoogle Scholar

- Selvnes H, Büttner V, Hafner A. Evaluation of a pillow-plate heat exchanger for a pump-circulated CO2 refrigeration system. In: Proceedings of the 14th IIR Gustav Lorentzen conference on natural refrigerants (GL2020), Kyoto, Japan, 7–9 December; 2020. pp. 159–64. https://doi.org/10.18462/iir.gl.2020.1094

- Sevault A, Næss E. Active latent heat storage using biowax in a central heating system of a ZEB living lab. In: 14th IIR Gustav Lorentzen conference on natural refrigerants (GL2020), Kyoto, Japan, 7–9 December; 2020. pp. 555–60. https://doi.org/10.18462/iir.gl.2020.1146

- Sundermeier S, aus der Wiesche S. Experimental investigation of high-speed flows past pillow plates. In: Proceedings of the ASME 2021 international mechanical engineering congress and exposition - Volume 10: fluids engineering, Virtual, Online, 1–5 November; 2021. https://doi.org/10.1115/IMECE2021-70223

- Selvnes H, Allouche Y, Hafner A. Experimental characterisation of a cold thermal energy storage unit with a pillow-plate heat exchanger design. Appl Therm Eng. 2021;199:117507. https://doi.org/10.1016/j.applthermaleng.2021.117507. ArticleCASGoogle Scholar

- Selvnes H, Allouche Y, Hafner A. A cold thermal energy storage unit for CO2 refrigeration using phase change material: first experimental results. In: Proceedings of the 9th IIR conference on Ammonia and CO2 refrigeration technologies, Ohrid, North Macedonia, 16–17 September; 2021. pp. 169–78. https://doi.org/10.18462/iir.nh3-co2.2021.0021

- Sundermeier S, Passmann M, Aus der Wiesche S, Kenig EY. Flow in pillow-plate channels for high-speed turbomachinery heat exchangers. Int J Turbomach Propuls Power. 2022;7(12):1–13. https://doi.org/10.3390/ijtpp7020012. ArticleGoogle Scholar

- Piper M, Tran JM, Kenig EY. CFD study of fluid dynamics and heat transfer for single-phase flow in the wavy channel between pillow plates. Chem Ing Tech. 2015;87(3):216–25. https://doi.org/10.1002/cite.201400091. ArticleCASGoogle Scholar

- Shih TH, Liou WW, Shabbir A, Yang Z, Zhu J. A new k-ε eddy viscosity model for high Reynolds number turbulent flows. Comput Fluids. 1995;24(3):227–38. https://doi.org/10.1016/0045-7930(94)00032-T. ArticleGoogle Scholar

- Piper M, Tran JM, Kenig EY. A CFD study of the thermo-hydraulic characteristics of pillow-plate heat exchangers. In: Proceedings of the ASME 2016 heat transfer summer conference (HT2016), Washington, DC, USA, 10–14 July; 2016. https://doi.org/10.1115/HT2016-7176

- Billard F, Laurence D. A robust k-ε-v2/k elliptic blending turbulence model applied to near-wall, separated and buoyant flows. Int J Heat Fluid Flow. 2012;33(1):45–58. https://doi.org/10.1016/j.ijheatfluidflow.2011.11.003. ArticleGoogle Scholar

- Piper M, Zibart A, Kenig EY. New design equations for turbulent forced convection heat transfer and pressure loss in pillow-plate channels. Int J Therm Sci. 2017;120:459–68. https://doi.org/10.1016/j.ijthermalsci.2017.06.012. ArticleGoogle Scholar

- Vocciante M, Piper M, Zibart A, Kenig EY. Numerical evaluation of different turbulence models for single-phase flow in the outer pillow-plate channel. Comput Aided Chem Eng. 2018;43:397–402. https://doi.org/10.1016/B978-0-444-64235-6.50072-3. ArticleCASGoogle Scholar

- Kumar S, Premachandran B, Subbarao PMV. Numerical simulation of fluid flow and heat transfer in a pillow plate channel. In: 16th international heat transfer conference (IHTC16), Beijing, China, 10–15 August; 2018. pp. 3175–82. https://doi.org/10.1615/IHTC16.cov.024055

- Zibart A, Kenig EY. Falling liquid film flow over the wavy surface of vertical pillow plates - a numerical investigation. In: 16th international heat transfer conference (IHTC16), Beijing, China, 10–15 August; 2018. pp. 6575–82. https://doi.org/10.1615/IHTC16.mpf.024081

- Piper M, Zibart A, Djakow E, Springer R, Homberg W, Kenig EY. Heat transfer enhancement in pillow-plate heat exchangers with dimpled surfaces: a numerical study. Appl Therm Eng. 2019;153:142–6. https://doi.org/10.1016/j.applthermaleng.2019.02.082. ArticleGoogle Scholar

- Shirzad M, Aghajani Delavar M, Mousavi Ajarostaghi SS, Sedighi K. Evaluation the effects of geometrical parameters on the performance of pillow plate heat exchanger. Chem Eng Res Des. 2019;150:74–83. https://doi.org/10.1016/j.cherd.2019.06.032. ArticleCASGoogle Scholar

- Shirzad M, Mousavi Ajarostaghi SS, Aghajani Delavar M, Sedighi K. Improve the thermal performance of the pillow plate heat exchanger by using nanofluid: Numerical simulation. Adv Powder Technol. 2019;30:1356–65. https://doi.org/10.1016/j.apt.2019.04.011. ArticleCASGoogle Scholar

- Selvnes H, Allouche Y, Sevault A, Hafner A. A CFD analysis for the performance assessment of a novel design of plates-in-tank latent storage unit for freezing applications. In: Proceedings of the 8th conference on Ammonia and CO2 refrigeration technologies, Ohrid, North Macedonia, 11–13 April; 2019. pp. 303–10.

- Selvnes H, Allouche Y, Sevault A, Hafner A. CFD modeling of ice formation and melting in horizontally cooled and heated plates. In: Eurotherm seminar #112 - advances in thermal energy storage, Lleida, Spain, 15–17 May; 2019.

- Passmann M, aus der Wiesche S, Kenig EY. On the low and high speed flow of gases through pillow plate channels. In: Proceedings of the ASME-JSME-KSME 2019 joined fluids engineering conference - Volume 1: fluid mechanics, San Francisco, California, USA, 28 July-1 August; 2019. doi https://doi.org/10.1115/AJKFluids2019-4933

- Kumar S, Premachandran B, Subbarao PMV. Large eddy simulation of single-phase forced convection in pillow plate channel with periodic boundary conditions. Int J Heat Mass Transf. 2020;149:119176. https://doi.org/10.1016/j.ijheatmasstransfer.2019.119176. ArticleGoogle Scholar

- Eldeeb R, Aute V, Radermacher R. Pillow plate heat exchanger weld shape optimization using approximation and parallel parameterized CFD and nonuniform rational B-splines. Int J Refrig. 2020;110:121–31. https://doi.org/10.1016/j.ijrefrig.2019.10.024. ArticleGoogle Scholar

- Lardeau S, Billard F, Development of an elliptic-blending lag model for industrial applications. In: 54th AIAA aerospace sciences meeting 2016, San Diego, California, USA. 2016. doi https://doi.org/10.2514/6.2016-1600

- Al-Turki YA, Yarmohammadi A, Alizadeh A, Toghraie D. Numerical investigation of nanofluid flow and heat transfer in a pillow plate heat exchanger using a two-phase model: effects of the shape of the welding points used in the pillow plate. Z Angew Math Mech. 2021. https://doi.org/10.1002/zamm.202000300. ArticleGoogle Scholar

- Kumar S, Premachandran B, Subbarao PMV. Performance analysis of the pillow plate channel using artificial neural network. Int J Therm Sci. 2022;172:107275. https://doi.org/10.1016/j.ijthermalsci.2021.107275. ArticleGoogle Scholar

- Norouzi A, Sodagar-Abardeh J, Arabkoohsar A, Ismail KAR. Investigating thermo-hydraulic behavior of pillow plate heat exchangers using entropy generation approach. Chem Eng Process: Process Intensif. 2022;174:108887. https://doi.org/10.1016/j.cep.2022.108887. ArticleCASGoogle Scholar

- Ghasemi K, Tasnim S, Mahmud S. Second law analysis of pillow plate heat exchanger to enhance thermal performance and its simulation studies. Heat Mass Transf. 2023;59(3):55–66. https://doi.org/10.1007/s00231-022-03245-8. ArticleCASGoogle Scholar

- Tong Z, Yang Q, Tong S, Chen X. Two-stage thermal-hydraulic optimization for pillow plate heat exchanger with recirculation zone parameterization. Appl Therm Eng. 2022;215:119033. https://doi.org/10.1016/j.applthermaleng.2022.119033. ArticleGoogle Scholar

- Arsenyeva OP, Kapustenko PO, Vasilenko OA, Tran JM, Kenig EY, The estimation of heat transfer area of pillow-plate heat exchangers for water heating. Bicник HTУ «XПI». 2017; 41(1263):3–9

- Tran JM, Piper M, Kenig EY, Single-phase flow and condensation in pillow-plate condensers. In: Bart HJ, Scholl S, (Ed.) Innovative heat exchangers. Springer: Cham. 2018; pp. 247–65. doi https://doi.org/10.1007/978-3-319-71641-1_8

- Scholl S, Pillow plate heat exchangers as falling film evaporator or thermosiphon reboiler. In: Bart HJ, Scholl S (ed.) Innovative heat exchangers. Cham: Springer.2018; pp 267–94. doi https://doi.org/10.1007/978-3-319-71641-1_9

- Vocciante M, Kenig EY. Pillow-plate heat exchangers: an overview on advances, limitations, and prospects. Chem Eng Trans. 2021;88:865–70. https://doi.org/10.3303/CET2188144. ArticleGoogle Scholar

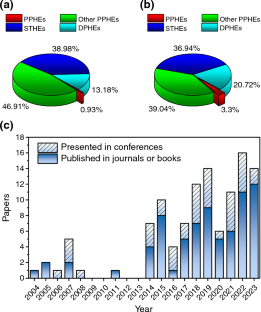

- Mastani Joybari M, Selvnes H, Sevault A, Hafner A. Potentials and challenges for pillow-plate heat exchangers: State-of-the-art review. Appl Therm Eng. 2022;214:118739. https://doi.org/10.1016/j.applthermaleng.2022.118739. ArticleGoogle Scholar

- Dittus FW, Boelter LMK. Heat transfer in automobile radiators of the tubular type. Univ Calif Publ Entomol. 1930;2(13):443–61. Google Scholar

- Patankar SV, Liu CH, Sparrow EM. Fully developed flow and heat transfer in ducts having streamwise-periodic variations of cross-sectional area. ASME J Heat Transf. 1977;99(2):180–6. https://doi.org/10.1115/1.3450666. ArticleGoogle Scholar

- Menter FR. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994;32(8):1598–605. https://doi.org/10.2514/3.12149. ArticleGoogle Scholar

- Rodi W, Experience with two-layer models combining the k-ɛ model with a one-equation model near the wall. In: 29th Aerospace Sciences Meeting, Reno, NV, USA, 1991; 10: 1991. doi https://doi.org/10.2514/6.1991-216

- Wolfshtein M. The velocity and temperature distribution in one-dimensional flow with turbulence augmentation and pressure gradient. Int J Heat Mass Transf. 1969;12(3):301–18. https://doi.org/10.1016/0017-9310(69)90012-X. ArticleGoogle Scholar

- Webb RL. Performance evaluation criteria for use of enhanced heat transfer surfaces in heat exchanger design. Int J Heat Mass Transf. 1981;24(4):715–26. https://doi.org/10.1016/0017-9310(81)90015-6. ArticleGoogle Scholar

- Martin H. The generalized Lévêque equation and its practical use for the prediction of heat and mass transfer rates from pressure drop. Chem Eng Sci. 2002;57(16):3217–23. https://doi.org/10.1016/S0009-2509(02)00194-X. ArticleCASGoogle Scholar

- Petukhov BS. Heat transfer and friction in turbulent pipe flow with variable physical properties. Adv Heat Transf. 1970;6:503–64. https://doi.org/10.1016/S0065-2717(08)70153-9. ArticleGoogle Scholar

- Mastani Joybari M, Selvnes H, Vingelsgård E, Sevault A, Hafner A. Parametric study of low-temperature thermal energy storage using carbon dioxide as the phase change material in pillow plate heat exchangers. Appl Therm Eng. 2023;221:119796. https://doi.org/10.1016/j.applthermaleng.2022.119796. ArticleCASGoogle Scholar

- Sevault A, Vullum-Bruer F, Tranås OL. Active PCM-based thermal energy storage in buildings. In: Cabeza LF, editor. Encyclopedia of Energy Storage: Volume 1. Elsevier: NJ. 2022. pp. 453-69. doi https://doi.org/10.1016/B978-0-12-819723-3.00008-1

- Seider WD, Lewin DR, Seader JD, Widagdo S, Gani R, Ng KM. Product and process design principles: synthesis, analysis and evaluation. 4th ed. New York: Wiley; 2017. Google Scholar

Acknowledgements

The current work is supported by computational resources provided by the Australian Government at the University of New South Wales under the National Computational Merit Allocation Scheme (NCMAS).